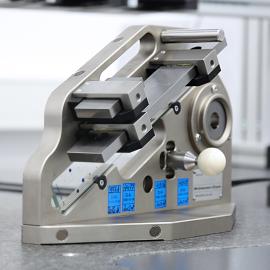

References and Checks

Coordinate measuring machines are reliable in their measuring accuracy – however they need to be routinely qualified and checked. CMM checks are used for standard-compliant accuracy checks, and reference bodies (spheres and other gauges) are used to qualify sensors and styli in everyday life.

600332-9168-000

- Length (L)

- 214,0 mm

12.094,00 krexcl. VAT

Available

8.922,00 krexcl. VAT

Made to Order

600332-8446-001

- Ø Sphere (DK)

- 30,0 mm

- Length (L)

- 85,0 mm

- Styl. Tip Mat.

- Ceramic

9.885,00 krexcl. VAT

Expected soon

600332-9266-000

- Ø Sphere (DK)

- 30,0 mm

- Length (L)

- 364,0 mm

- Styl. Tip Mat.

- Ceramic

18.217,00 krexcl. VAT

Expected soon

41.135,00 krexcl. VAT

Expected soon

600332-9265-001

- Ø Sphere (DK)

- 30,0 mm

- Length (L)

- 214,0 mm

- Styl. Tip Mat.

- Ceramic

31.068,00 krexcl. VAT

Expected soon

5.777,00 krexcl. VAT

Available

626106-0045-000

- Ø Sphere (DK)

- 30,0 mm

- Length (L)

- 58,0 mm

- Styl. Tip Mat.

- Ceramic

6.329,00 krexcl. VAT

Made to Order

12.646,00 krexcl. VAT

Expected soon

15.740,00 krexcl. VAT

Made to Order

600332-9165-000

- Length (L)

- 214,0 mm

11.388,00 krexcl. VAT

Expected soon

21.594,00 krexcl. VAT

Expected soon

600332-8445-000

- Ø Sphere (DK)

- 25,0 mm

- Length (L)

- 82,5 mm

- Styl. Tip Mat.

- Ceramic

5.303,00 krexcl. VAT

Available

149.952,00 krexcl. VAT

Expected soon

626106-9040-100

- Length (L)

- 400,0 mm

34.586,00 krexcl. VAT

Longer delivery time

600332-8455-000

- Ø Sphere (DK)

- 25,0 mm

- Length (L)

- 82,6 mm

- Styl. Tip Mat.

- Ceramic

4.814,00 krexcl. VAT

Available

137.113,00 krexcl. VAT

Expected soon

626106-9140-100

626106-9140-100

- Length (L)

- 400,0 mm

42.033,00 krexcl. VAT

Expected soon

600332-9265-000

- Ø Sphere (DK)

- 30,0 mm

- Length (L)

- 214,0 mm

- Styl. Tip Mat.

- Ceramic

16.099,00 krexcl. VAT

Expected soon

44.299,00 krexcl. VAT

Expected soon

7.438,00 krexcl. VAT

Available

600332-9486-000

- Ø Sphere (DK)

- 25,0 mm

- Length (L)

- 105,0 mm

- Styl. Tip Mat.

- Ceramic

9.919,00 krexcl. VAT

Available

600332-8447-000

- Ø Sphere (DK)

- 45,0 mm

- Length (L)

- 92,5 mm

- Styl. Tip Mat.

- Ceramic

12.415,00 krexcl. VAT

Made to Order

600332-8444-000

- Ø Sphere (DK)

- 15,0 mm

- Length (L)

- 77,5 mm

- Styl. Tip Mat.

- Ceramic

5.162,00 krexcl. VAT

Available

77 Items