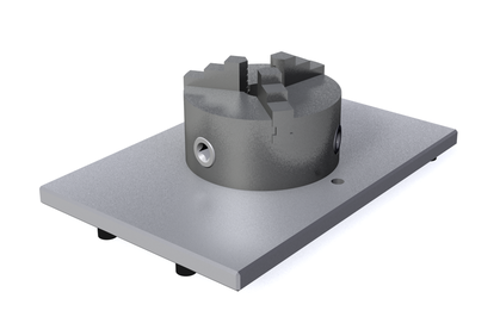

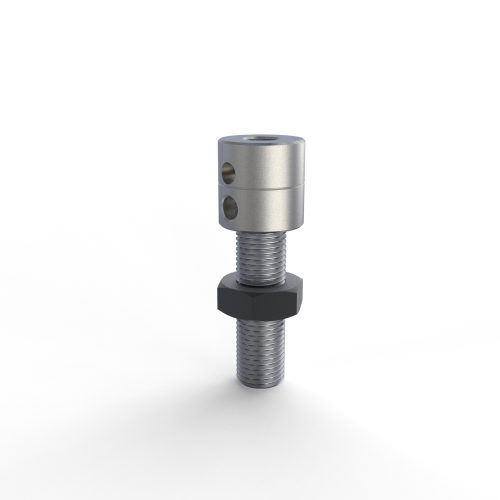

Workpiece Fixturing

Whether for tactile, optical or X-ray applications: Fixing the component on the measuring device is decisive in order to achieve meaningful and accurate measuring results. ZEISS clamping devices and accessories are designed to be universal: They are suitable for a wide variety of geometries and measuring devices. You can choose from well thought-out kits, the components of which can also be purchased separately, as well as universal clamping devices such as vices and three-jaw chucks.

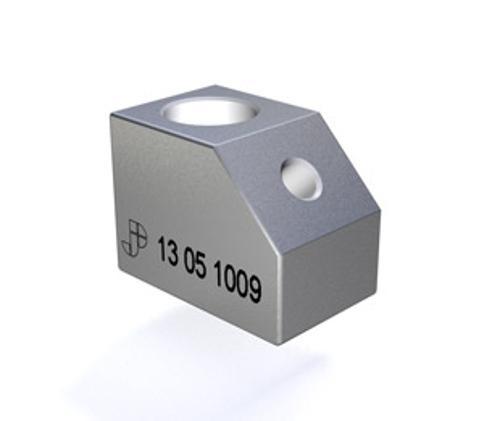

184,00 krexcl. VAT

Available

354,00 krexcl. VAT

Expected soon

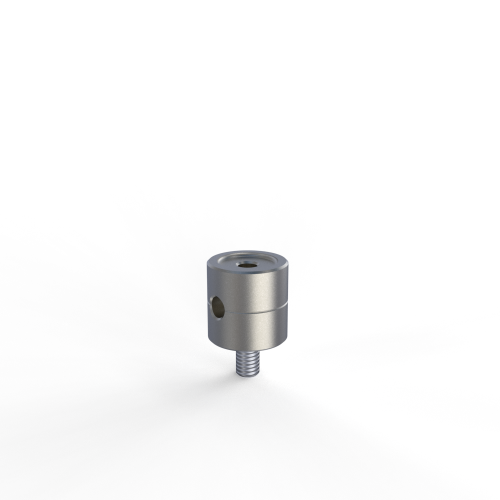

837,00 krexcl. VAT

Expected soon

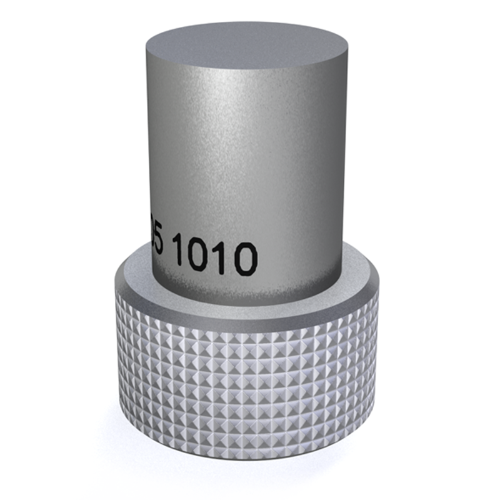

146,00 krexcl. VAT

Expected soon

131,00 krexcl. VAT

Available

17.000,00 krexcl. VAT

Expected soon

2.364,00 krexcl. VAT

Longer delivery time

10.136,00 krexcl. VAT

Available

229,00 krexcl. VAT

Expected soon

30.152,00 krexcl. VAT

Available